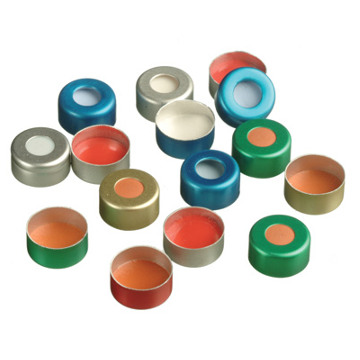

Crimp Caps

Crimp Caps for Autosampler Vials from Thermo Scientific

Minimize contamination from handling with convenient, pre-assembled Thermo Scientific 8 mm and 11 mm vial crimp caps, compatible with most HPLC and GC autosamplers.

Choose from Thermo Scientific National or Thermo Scientific Chromacol brands.

- Buy

- Features

-

- Aluminum crimp closures provide a secure leak-resistant seal

- Pre-assembled caps and septa are convenient and minimize contamination from handling

- 8 mm crimp top seal minimises exposure between sample solvent and septum

- Aluminum seals must be applied with a crimping tool

- Synthetic PTFE/Red Rubber seal is specially formulated for improved background performance

- First crimp cap with assembled aluminum liner for analysis of elastomers, polymers, phthalates, halogenated compounds and silicones

- First crimp cap with tight PTFE sealing disk due to additional silicone ring

- Specifications

-

PTFE/Natural Red Rubber Septa

PTFE/Natural Red Rubber are moderately priced seals for GC and HPLC with good chemical properties. They are ideal for multiple injections due to high resealability, but not as easy to penetrate as PTFE/Synthetic Red Rubber.

PTFE/Synthetic Red Rubber Septa

PTFE/Synthetic Red Rubber septa are an economical choice for general GC and HPLC applications. Used primarily for routine analysis in gas chromatography with FID, TCD and FPD detectors or HPLC with UV/Vis or RI detectors, PTFE/Synthetic Red Rubber septa offer good resealability and excellent chemical inertness before puncture. The low durometer of red rubber allows for easy needle penetration even with thin bore GC needles. PTFE/Red Rubber septa are not recommended for multiple injections with long run times or retention of samples for further analysis after initial puncture.

PTFE/Silicone Septa

PTFE/Silicone is the most versatile septum material offered in various formulations to address specific applications requirements. Extractables from PTFE/Silicone septa are generally at lower levels compared to other resealable materials. PTFE/Silicone septa are formulated for different hardness (durometer) meeting requirements of various needle types. Formulations offering highly consistent performance, lowest background/blank value, and good chemical compatibility, effective sealing/resealing and low penetration force make PTFE/Silicone septa suitable for all types of chromatographic applications. A thin film of PTFE is laminated to the side of the septum that faces the sample to limit exposure of the elastomer to the solvent. PTFE/Silicone septa are ideal for use in most HPLC and GC applications where resealability and purity are critical.

PTFE/Silicone/PTFE Septa

A layer of inert PTFE film is laminated to each side of high-purity, medium durometer silicone to form a septum that is resistant to coring, but still maintains good resealing characteristics. PTFE/Silicone/PTFE septa are recommended for the most critical applications such as ultratrace analysis, where there is a longer time between injections. PTFE/Silicone/PTFE septa provide superior performance with any autosampler employing a large diameter, blunt-tip needle. PTFE/Silicone/PTFE septa can have benefits when working with solvents that tend to attack silicone by protecting both sides of the elastomer.

PTFE Disk Septa

A solid disk of 0.010” thick pure PTFE offers superior chemical inertness against the most aggressive solvents. The thin membrane allows for penetration by most normal gauge metal HPLC needles. PTFE septa are not resealable and should not be used with highly volatile solvents, short cycle times or multiple injection methods. PTFE septa are rarely used for GC applications.

Polypropylene Septa

Chemically resistant polypropylene septa are available as thick disks inserted into closures. The surface for needle penetration is 0.01" thick allowing for use with most HPLC autosamplers. Polypropylene septa are not resealable and are intended for single injection use with aqueous based sample mixtures. Polypropylene septa offer better solvent compatibility compared to polyethylene, but piercing force is slightly higher.

Viton Septa

Viton septa are used in situations where a resealable septum is required for a sample matrix that aggressively attacks all other materials. Viton offers chemical resistance similar to PTFE along with limited ability to reseal after puncture. Viton septa have a high resistance to piercing and due to their high cost are considered to be the septum of last resort when all other materials are unsuitable.

- Literature

-

-

Thermo Scientific Sample Handling Catalogue

Contains details on Thermo Scientific's sample handling products

-

SAMPLE HANDLING TECHNICAL BROCHURE

Contains full technical information on Thermo Scientific's sample handling products

-